In this video, we present a clear example of how Vuototecnica solutions can solve taking problems; problems which are a result of poor management of vacuum sources or wrong plant and gripping system design.

You can see a gripping system, for metal kitchen skins, amended to include Vuototecnica maxigrip suction cups and M10 multistage ejectors.

Previously, the system used neoprene suction cups but they were subjected to strong deformation due to the continuous use and so they wore out faster. Especially in taking sink grooved part, the matter was even more problematic, because these suction cups had to adapt to the irregular surface and therefore they wore faster.

Vuototecnica modified the system by mounting the Maxigrip Benz cups, suitable for steel, even irregular, surfaces.

The lip of Maxigrip suction cups is extremely flexible and it allow them to better adapt to any surface – flat, concave or convex – with no risk of deforming or breaking the material, even when it is delicate and subtle.

As we can see from the foreground, in this video, suction cups are in firm contact with the grooves of the metal sink, and thanks Benz compound, they are also ideal on oiled or wet surfaces, as well as having much longer wearing times.

These cups can be provided in round and elliptical shape, flat or bellows, and they can boast a wide range of accessories (reductions, adapters, couplings).

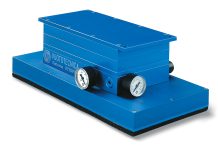

As regards the vacuum generation system, the previous one was replaced (it was made of single stage ejectors) with M10 pneumatic vacuum generators with multiple ejectors that guaranteed greater suction flow and a lower compressed air consumption.

As regards the vacuum generation system, the previous one was replaced (it was made of single stage ejectors) with M10 pneumatic vacuum generators with multiple ejectors that guaranteed greater suction flow and a lower compressed air consumption.

In the catalogue, you can find all products described so far and you can view designs.

Update your systems, please contact Vuototecnica!