It is impossible to think of many industrial sectors without the drying processes obtained thanks to vacuum.

The liquid inside the processed materials is evaporated reducing the pressure and eliminating the steam.

Compared to thermal drying process, using vacuum is faster and more delicate and it allows a considerable energy saving.

When an excess of heat could deteriorate the product or change its composition or when the surface to be dried is very large, vacuum solution is perfect.

Some application examples can be: drying of mud, wood, synthetic granules, ceramics and drying of delicate components.

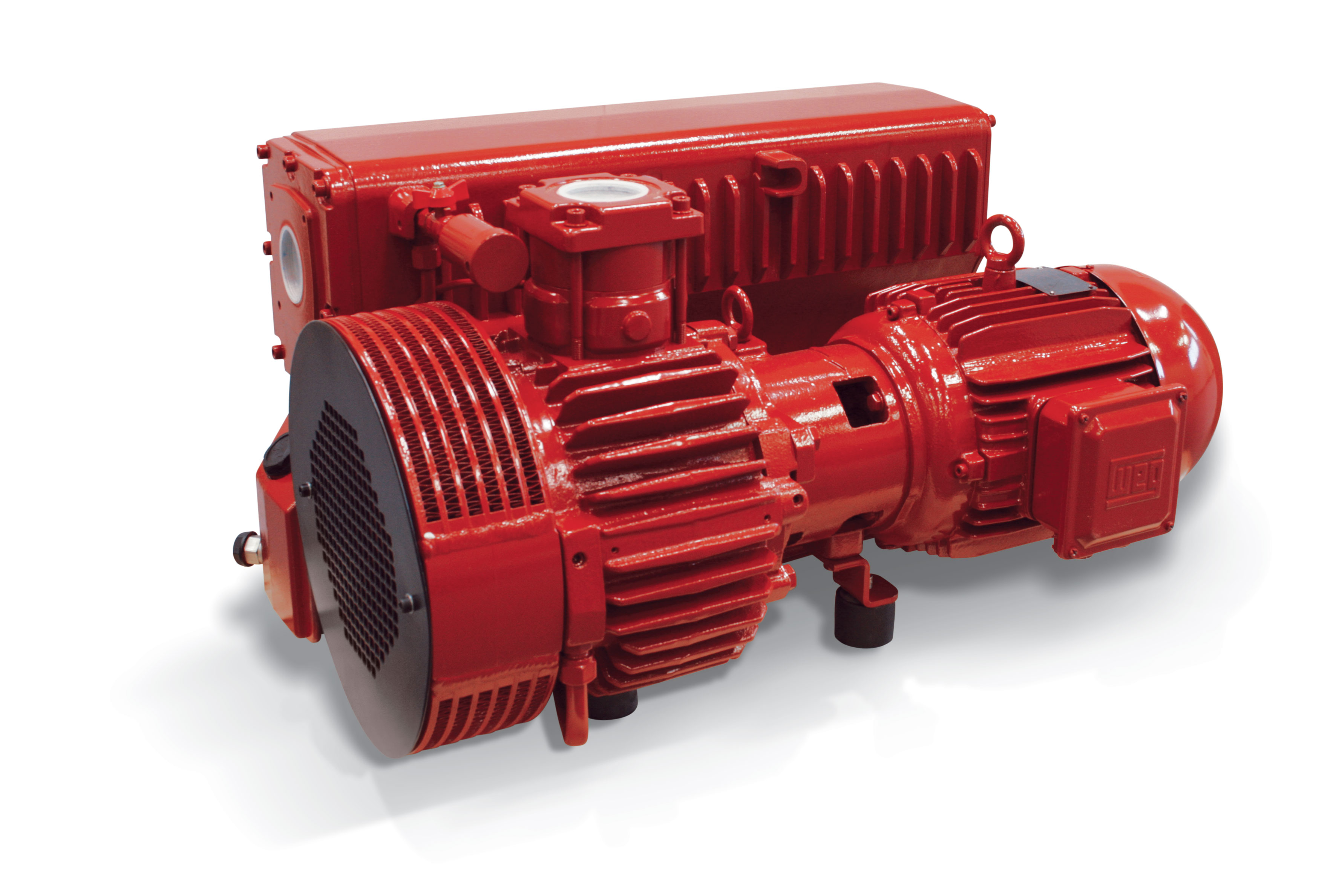

Vuototecnica RVP vacuum pumps, equipped with a ballast valve, have good compatibility with water steam given by degassing.

They are also suitable for continuous and heavy use and do not overheat, even after many hours, a useful feature when the drying processes take many hours.

Compliant with the latest European standards (IEC60034) and fitted with IE2 high energy efficiency electric motors as standard, they have an oil recovery tank, fitted with micro-fiber oil removal cartridges and remove fumes from the exhaust.

Moreover they do not need great maintenance because they are produced with quality materials, despite the excellent market price.

On the intake, the check valve is integrated in the pumps and it is standard.

It is also possible to request a suitable filter to retain impurities.

If you have different needs, consider that Vuototecnica designs from small rotary vane vacuum pumps to large vacuum systems, up to complete systems.

To learn more, please visit www.vuototecnica.net