In the following video you can see a Fanuc robot feeding a metal sheet bending press.

It is a process that is often used to produce metale shelves, for example, and it generally requires the presence of a person to position the sheet by hand, under the press, to proceed from time to time shaping the piece.

In this case, a robot takes care of it, with several advantages in terms of safety for the operator and positioning speed and accuracy.

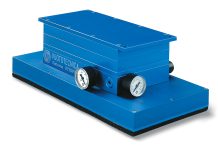

The robot’s gripping hand is implemented with Vuototecnica Maxigrip suction cups which, as you can see, guarantee stability and precision, both vertically and horizontally to the sheet metal.

So, the piece can be formed and folded according to the shape mounted on the press, without the risk of slipping and with greater speed than normal.

The grip is exceptional, even when in contact with wet or oiled sheets.

Try it for yourself: www.vuototecnica.net