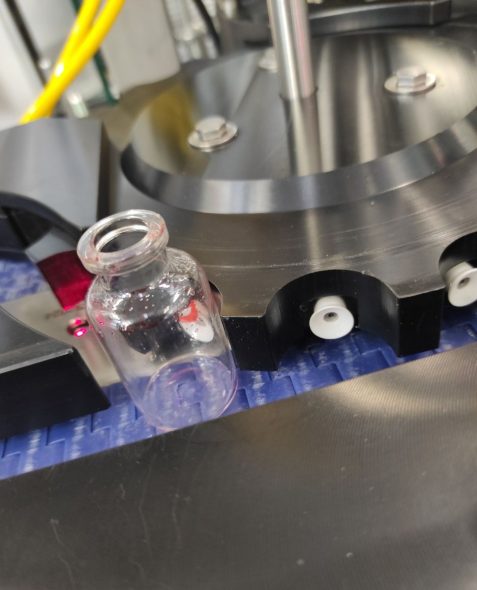

The following video shows an innovative solution for pharmaceutical packaging: a system for picking up and transporting vials that uses decentralized vacuum generation.

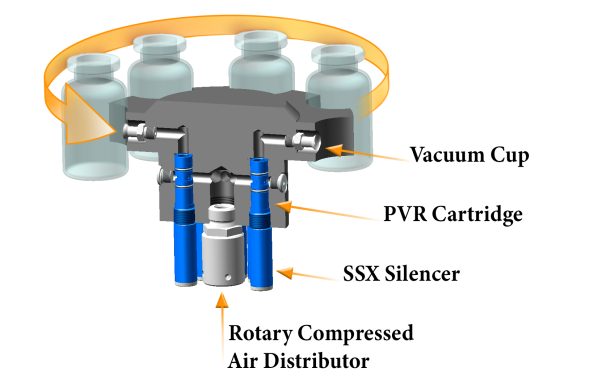

This application, which uses the proven PVR1 and PVR4 vacuum cartridges, is a perfect example of how optimizing filling and packaging machines with rotating structures.

Traditionally, manufacturers of these machines rely on a centralized vacuum pump. The vacuum is then distributed to each individual suction cup via a rotary compressed air distributor, often designed and manufactured in-house.

This approach has two main critical issues:

1. The need to build a custom-made rotary distributor.

2. The need to oversize the pump to compensate for the losses that inevitably occur when, at the start of rotation, some suction cups are still without vials, negatively affecting the efficiency of the entire circuit.

Vuototecnica’s PVR cartridges revolutionize this paradigm. By installing a PVR1 or PVR4 cartridge for each suction cup, vacuum generation is decentralized. Each gripping point becomes an independent unit, overcoming the limitations of traditional systems and offering significant advantages.

The adoption of PVR cartridges leads to concrete benefits for both the machine manufacturer and the end user:

- Manufacturers are no longer required to design and build complex rmachines. They can integrate rotary distributors, standard components that are easier and quicker to find on the pneumatics market.

- It is no longer necessary to oversize the vacuum source. Since each suction cup generates vacuum independently, the absence of a vial on one suction point does not affect the correct functioning of the others. The system is more stable, efficient, and leakage-free.

- A micro vacuum switch (such as model 12 05 10 P) can be installed on each PVR cartridge. This provides accurate feedback on the grip of each suction cup and allows the wear status of each suction cup to be monitored, a level of control that is impossible to achieve with a centralized system.

- PVR cartridges, installed near the suction cup, have no moving parts and are designed to be extremely strong. They can absorb dust and impurities, passing them to the free flow silencer (SSX) exhaust. This eliminates the need to install dedicated suction filters, reducing complexity and costs.

- The cartridges operate with low-pressure compressed air (only 2-3 bar), while still ensuring excellent suction flow and an optimal vacuum level for this application (approximately -75 kPa).

- Maintenance is quick and can be carried out by the end user. The cartridges can be unscrewed, cleaned with a jet of compressed air, and reused immediately, minimizing machine downtime.

- In short, the adoption of PVR1 and PVR4 vacuum cartridges not only optimizes the performance and reliability of rotary packaging machines, but also reduces design, construction, and maintenance time and costs.

To find out all the details about vacuum decentralization and specifications, please visit: www.vuototecnica.net.