In the following video, a robot equipped with suction cups and the MSVE multifunction vacuum generator by Vuototecnica safely moves the polystyrene interlayers during the creation of a pallet.

As you can see from the images, the various phases are carried out precisely and without load losses, but what you can’t see is even more important.

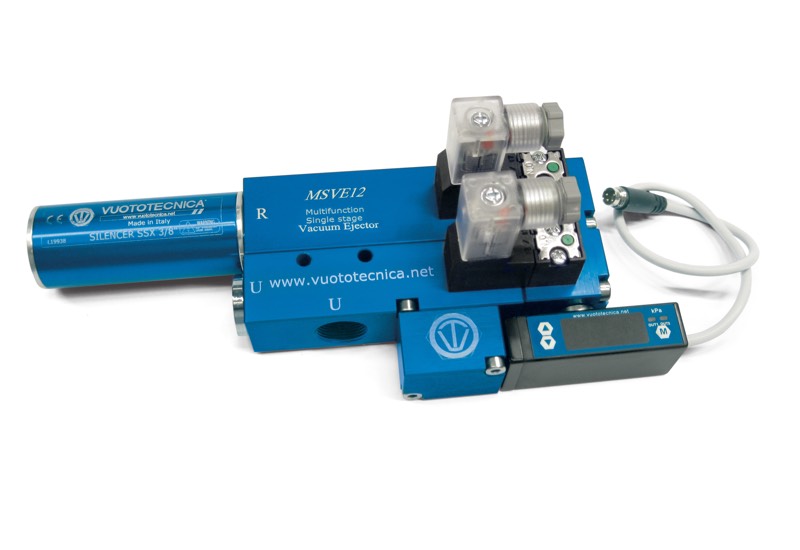

The MSVE generator integrates the main functions in a single device, managing the creation of a vacuum and a counter-blow, particularly useful in environments where residues could cause annoying blockages.

MSVEs work with various types of suction cups and can handle a wide variety of materials, from metals to glass, to delicate polystyrene.

Energy efficiency is also guaranteed by the energy saving cables that minimize compressed air consumption, ensuring low impact operations. This is possible thanks to the optimized pressure management and the micro-solenoid valve activation system of the MSVEs that intervenes to maintain the vacuum within the preset parameters.

The check valve maintains the vacuum even in the event of a sudden power interruption. And thanks to the precise control of the release and counter-blow, handling is simplified as well as accurate, and the work area remains clean.

The result? A safe, efficient and energy-efficient packaging process.

To download MSVE technical data sheets: www.vuototecnica.net.