According to the International Federation of Robotics’ World Robotics Report 2025, cited by leading industry magazines, Italy remains a global player in automation, ranking as the second largest market in Europe in terms of the number of industrial robots installed and achieving a prestigious fifth place globally.

With 8783 new units put into operation in 2024, Italy is preceded in Europe only by Germany and surpassed globally only by giants such as China, Japan, South Korea, and the United States, demonstrating extraordinary resilience despite the general slowdown in the manufacturing sector.

An analysis of the national production industry shows that the metalworking and machinery sector leads the ranking with 5600 installations, followed by the automotive sector, which, with 2600 new robots, is benefiting from the push towards electric vehicles and battery production, while sectors such as medical, plastics, and food & beverage are showing signs of steady growth between 4% and 10%.

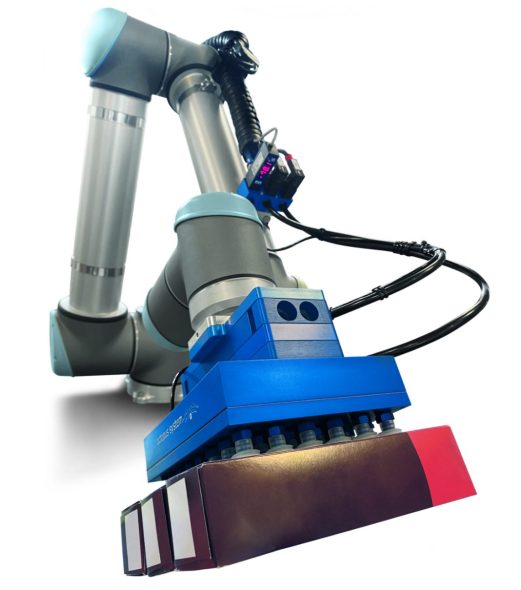

In this scenario, the most widespread applications are in machine automation and handling operations, which account for over half of new installations, with significant growth also in packaging and palletizing.

In such a dynamic context, where the precision and efficiency of robotics become fundamental to competitiveness, Vuototecnica plays a key role by offering cutting-edge solutions for robotic handling, such as Octopus gripping systems, vacuum generators, and various types of suction cups designed to ensure maximum reliability in every industrial application, including the management of small batches where collaborative robots – which today represent about 15% of the national total – require flexibility and quick setup.

If you want to find out how to optimize your gripping systems and remain competitive in the market, you can explore the solutions and application cases available by browsing the blog categories or contacting Vuototecnica designers on the website www.vuototecnica.net.