In recent years, industrial automation made great progress, integrating artificial intelligence, increasingly accurate sensors, and advanced gripping systems. In this context, vacuum technology remains one of the most versatile and efficient technologies in many sectors: from packaging to logistics, from collaborative robotics to the food industry.

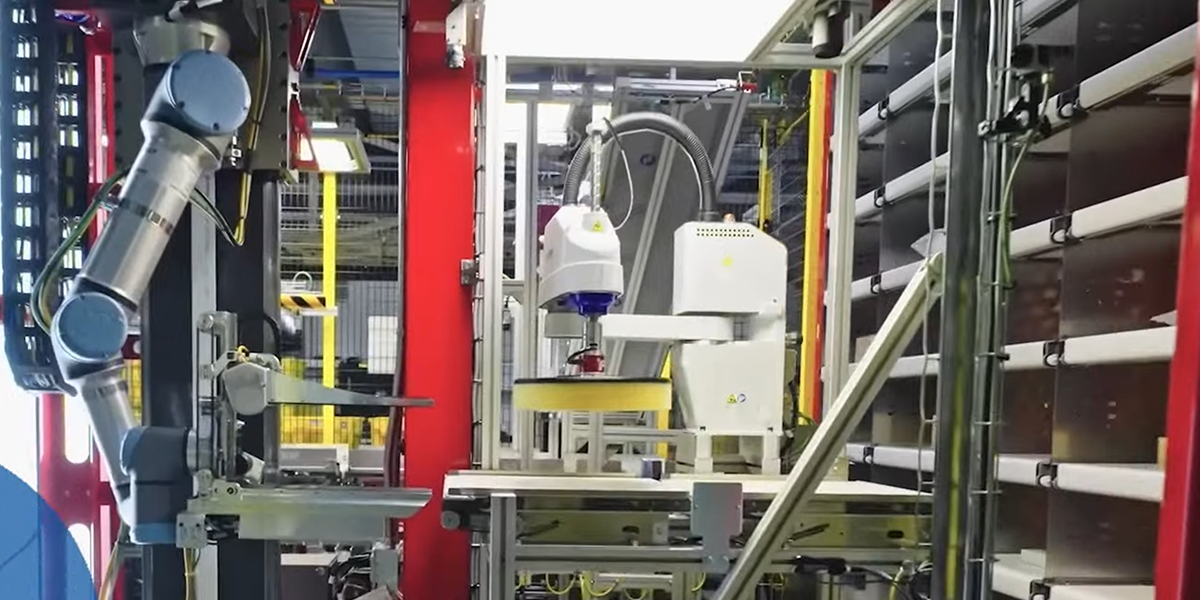

A concrete and highly topical example comes from a logistics giant. Amazon introduced Vulcan, its first warehouse robot with advanced tactile capabilities. Unlike traditional robots, it can sense the pressure exerted on objects and adjust its gripping force to adapt to any type of material or shape.

It is already capable of handling around 75% of the items in warehouses and is structured like a classic robotic arm. But what makes it truly innovative is its motorized spatula, which allows it to explore shelves, combined with an intelligent suction cup system guided by an AI-based camera. This allows Vulcan to pick up objects with extreme precision and delicacy, an essential quality in sorting centers where there is a huge variety of items.

Vulcan is currently in operation at both the logistics center in Hamburg, Germany, and in Spokane, USA, where it has already processed over 500,000 orders. The robot works closely with human operators, relieving them of the most strenuous tasks and improving efficiency and safety at work.

Vulcan demonstrates how suction cups are an irreplaceable gripping technology in modern robotic systems. Thanks to their ability to adapt to irregular shapes, delicate surfaces, and different materials, they offer a flexible, efficient, and safe solution for every handling requirement.

Vuototecnica has been a benchmark in the world of vacuum technology for many years. Its systems are designed to integrate with the most advanced robots and support industrial automation with reliable, customizable, and sustainable solutions.

To discover how vacuum can revolutionize your production system, visit www.vuototecnica.net.