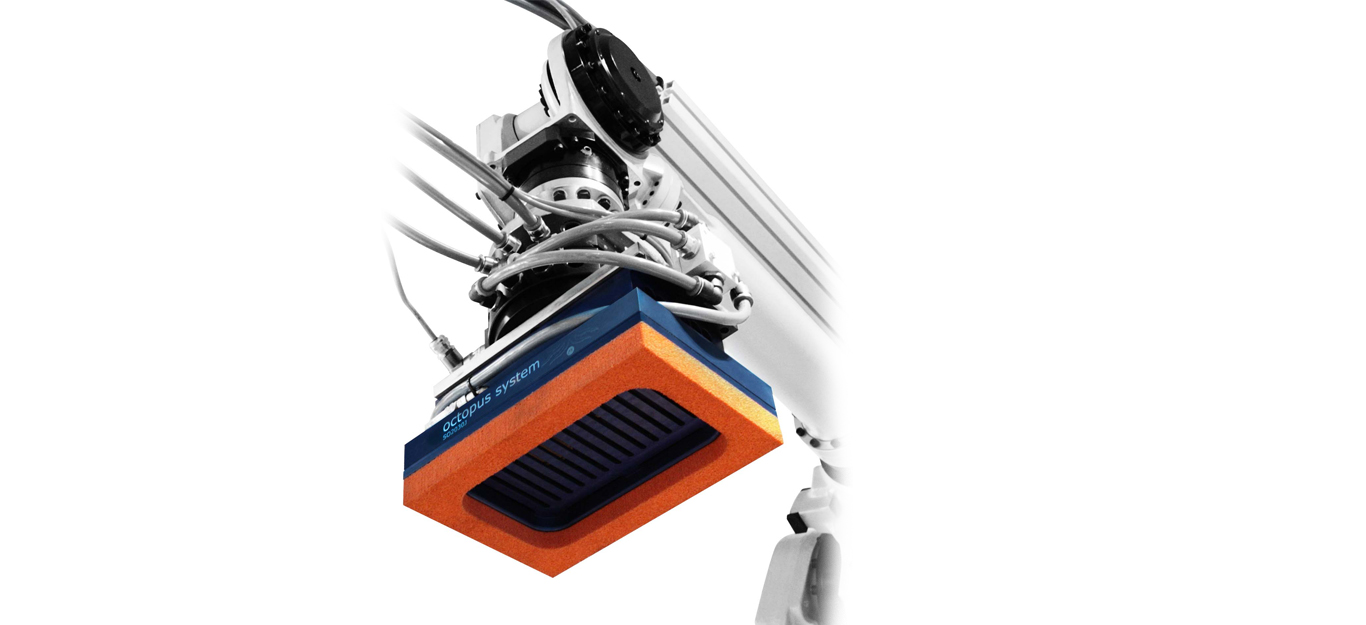

In the following video you can see SO2030J Octopus vacuum gripping system in action when handling horse bedding and creating pallets.

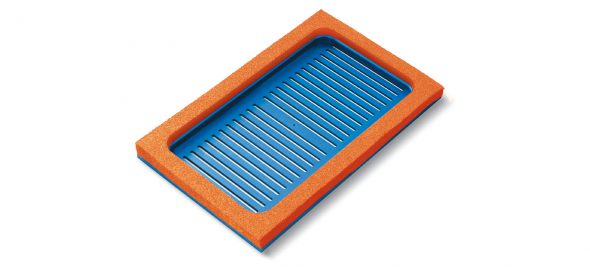

The “geranium” sponge rubber plate takes and releases the customer’s bags efficiently. As you can see, in fact, the consistency of the bag, containing chips and other loose materials, is not an obstacle for the Octopus, just as the plastic film of the packaging is not an obstacle.

The sponge rubber plate does not allow the occlusion and is made with a special high density compound, which has an excellent elasticity and whose durability is guaranteed over time, even after many processing cycles.

The deformation of the bag is practically zero and the loss of vacuum is minimal. (The lifting force is calculated considering a vacuum level of at least -75 Kpa).

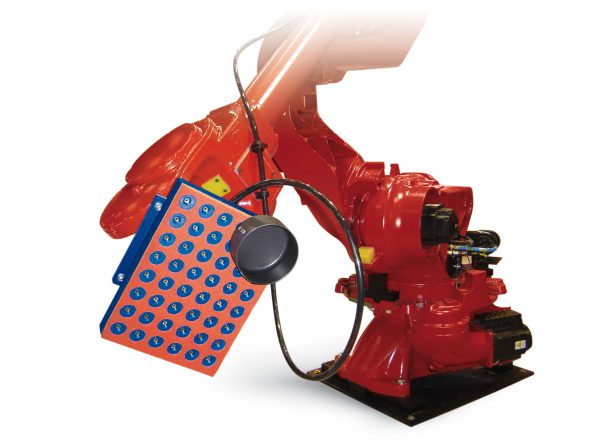

All the advantages of the Octopus remain: it is not necessary to reposition the suction cups every time, even when the robot is required to perform different tasks; it is also ideal when the surface of the objects to be handled occupies only 5% of the suction plane; it can operate vertically, horizontally, tilted and even upside down with respect to the gripping plane of the objects.

Octopus wins over all other systems in the creation and unloading of pallets, in different industrial sectors.

To find out which Octopus gripping system is right for you, contact Vuototecnica’s designers without obligation or browse the catalogue at www.vuototecnica.net.