In the intricate realm of industry and mechanics, technical jargon might seem distant from our daily experiences. However, the underlying concepts often find parallels in everyday scenarios. Consider vacuum ejectors, also known as venturi or vacuum generators, which are pivotal in numerous industrial contexts.

These devices operate on an intriguing principle observable even during a car ride.

Imagine igniting a cigarette (or for non-smokers, imagine a lit stick of incense) while in a moving car with the window cracked open. You’ll notice the smoke being drawn out. This is due to the Venturi effect, where the swift passage of air outside lowers the pressure by the window, creating a vacuum that pulls the smoke outwards.

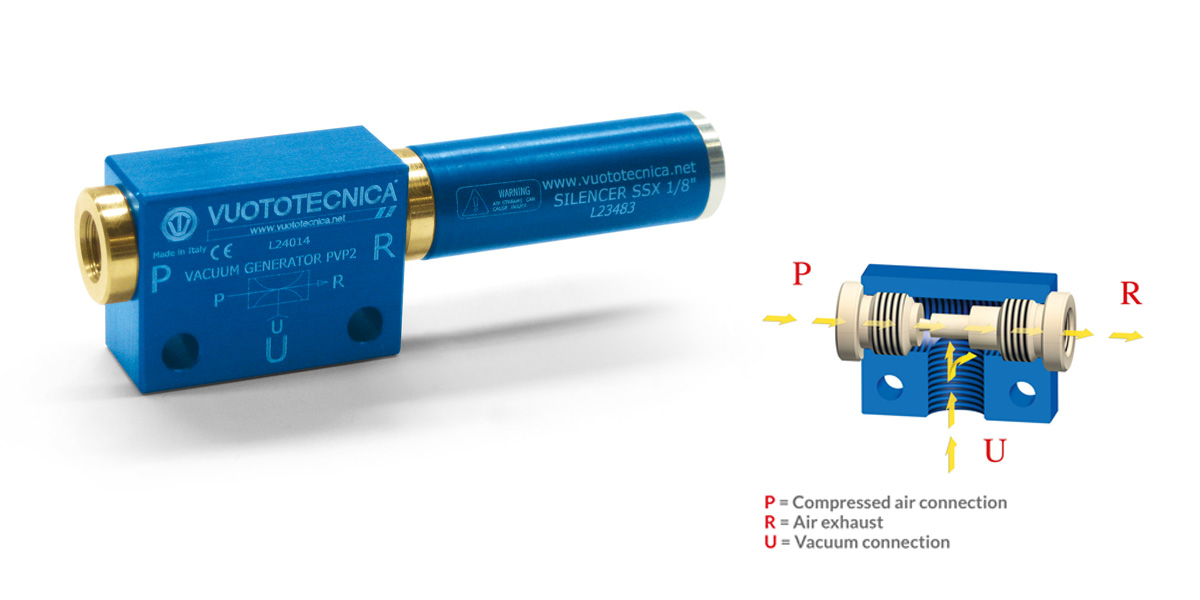

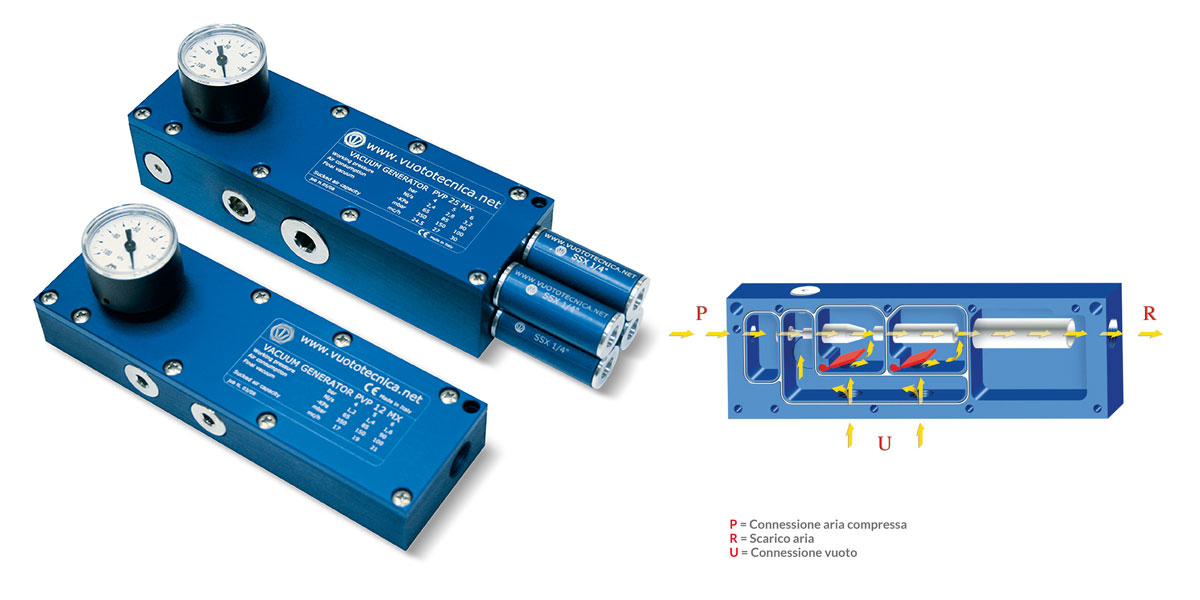

Vacuum ejectors harness this very principle, utilizing compressed air or fluids to create a vacuum.

Unlike traditional vacuum pumps driven by mechanical parts and electric motors, ejectors leverage fluid dynamics for their operation. This simplicity and lack of moving parts mean less maintenance and greater longevity.

The industry often sees a divide between companies specializing in Venturi-based systems and those focusing on vacuum pumps, with each camp advocating for the merits of their chosen technology. Yet, both approaches offer valid vacuum solutions, with the choice between them hinging on the specific application’s demands, performance needs, and cost considerations.

Ejectors come in both single-stage and multi-stage designs. Single-stage ejectors, being simpler, suit applications where speed is of the essence, despite being less air-efficient. On the other hand, multi-stage ejectors, though more complex, excel in air efficiency and vacuum strength.

The decision between a single-stage and a multi-stage ejector boils down to the application’s unique requirements, weighing the trade-offs between response speed and energy efficiency.

Vacuum ejectors find their use in a wide array of industrial tasks, from handling fragile items to establishing controlled environments in production processes. Choosing the right type involves a thorough analysis of the operational cycle, vacuum needs, and energy efficiency, guiding towards a sustainable and cost-effective solution.

So, the next time you’re in a car and observe smoke whisked swiftly out of an open window, think of ejectors. Rooted in a simple physical principle, they are instrumental in myriad industrial applications, demonstrating how everyday observations can fuel technological innovation. For more insights, visit www.vuototecnica.net.