The latest trend in food packaging is the use of recyclable cardboard instead of plastic.

Several companies and multinationals chose to modify the packaging of some leading products to pursue the concept of environmental sustainability.

Ultralight materials based on wood fibres for the trays of ready-to-eat meals, re-sealable bags made of recyclable paper for potatoes and carrots (which ensure the freshness of the product for longer), recycled cardboard jars for jams able to keep up with the variety of types and formats.

Plastic is being replaced and it becomes necessary within the supply chain (production, packaging, distribution) to also change the equipment and robots.So it turns out that considering overall equipment performance, maintenance costs, wear and tear on parts, and other factors that come into play when considering the overall impact of a machine, it’s worth it.

All that remains is to consider gripping solutions that meet the needs of energy savings and environmental sustainability.

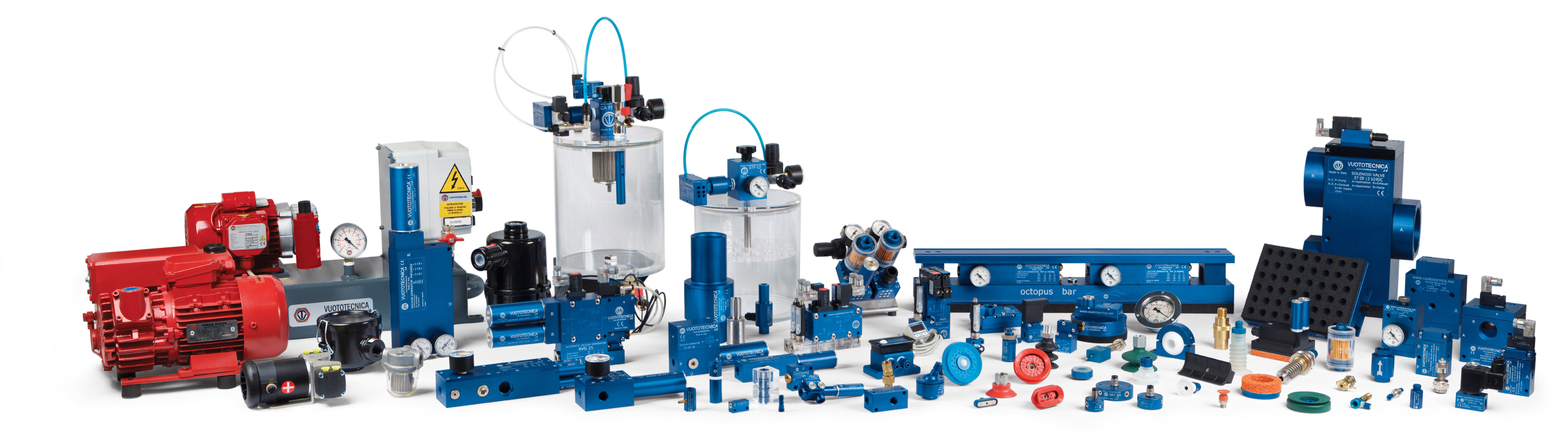

And in this sense, Vuototecnica is the ideal partner for the reconfiguration of robot gripping hands, thanks to the various product management possibilities.

Vuototecnica suction cups, vacuum generators and vacuum gripping systems not only allow for energy savings and efficiency, but also show special care for the product. They do not damage the packaging and avoid unwanted occlusions and clogging that are often found in dusty environments (such as those in which paper and cardboard are used).

Read more: www.vuototecnica.net