Vuototecnica designed a special set, code DV300VRVP300FS50BP, for vacuum clamping non-magnetic metal materials on board large machining centres.

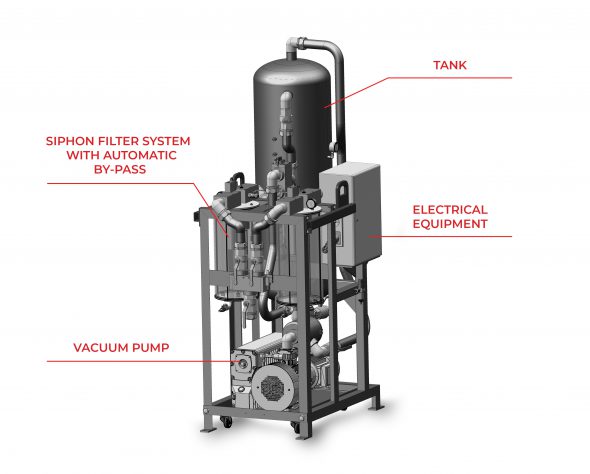

It is a servo vacuum system consisting of a vertical vacuum storage tank, FSBP50 by-pass filters, an oil bath vane pump model RVP300, and an electrical control panel.

In the basic set, the 300 litre vertical storage tank is vacuum tight and mounts the electrical panel to control the operations, while the RVP pump creates and maintains the constant vacuum level previously established by the customer via digital vacuum switch.

The filters prevent the pump from sucking in lubricant-coolant liquids that may possibly be on the clamping table of the machining centre, and operate autonomously, suctioning and discharging the retained liquids, without costly stops. In fact, there is no need to stop the pump or to exclude the vacuum. The energy savings are unquestionable and the speed of application is evident.

Thanks to this mechanism, in addition, objects in the grip are not subjected to unwanted vibrations: the grip remains firm in every step.

It is also possible to choose the most suitable pump for the application, considering its size and type. The same applies to the filters and the tank (available for different volumes).

Customisation is important to Vuototecnica. If you want to find out what’s right for you: www.vuototecnica.net