For the packaging sector and in particular when it comes to taking open or closed cans, jars or tins, to move them from the pallet to the filling/production line or vice versa, there is a need to assess the particular conformation of the objects to be handled and therefore to open an engineering-partner relationship with the customer and find a solution for the gripping hands of the robots involved.

Whether the jars are made of glass or other material, whether they have lids or not, in order not to get caught with the wrong gripping hands, several factors need to be considered, as very often these are fragile objects and with traditional suction cups it could be a game of lose-lose.

As you can see in the video, the PH and P2H suction plates are perfect for handling closed jars of jam, but the same would happen with open containers.

The grip is always firm on the pressurised lid and the PH and P2H plates respond perfectly to movement, easily compensating for the unevenness in height that can very often be found on pallets.

A plus is that the well-known flexibility of Octopus allows the user to take containers of different diameters and shapes without having to change the grip plate.

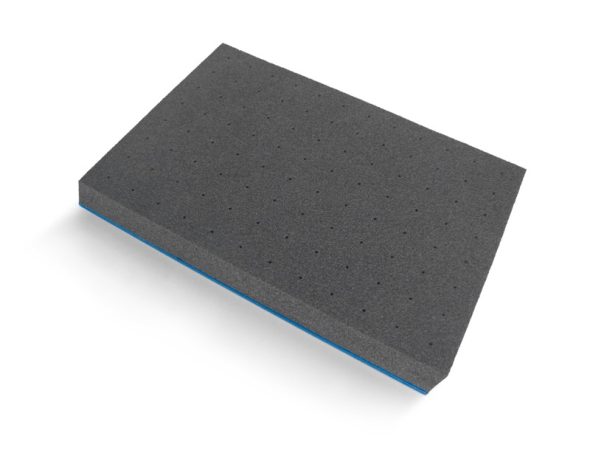

The PH plate has a sponge rubber thickness of 15 mm and the P2H of 30, to be considered according to the type of object to be gripped and the height compensation required.

On the product data sheets, it is also explained how to calculate the lifting force of open containers, which must be directly proportional to the degree of vacuum generated on the surface of the mouth of the bottle to be gripped.

To find out more about the Octopus gripping system, its applications, and to learn about the characteristics of PH and P2H suction plates, please visit www.vuototecnica.net or contact Vuototecnica designers.