Drying in food and pharmaceutical market is the process in which the liquid present in a solid mass is removed by introducing heat from outside.

It can be water or a solvent: this operation can create problems in all cases, due to the high temperatures.

This is why vacuum can come to the rescue when it comes to drying:

- It reduces the energy investment.

- It avoids damaging heat-sensitive materials because boiling and subsequent evaporation take place more quickly.

Vuototecnica is able to supply complete components for the control and distribution of vacuum in the chamber, for similar applications.

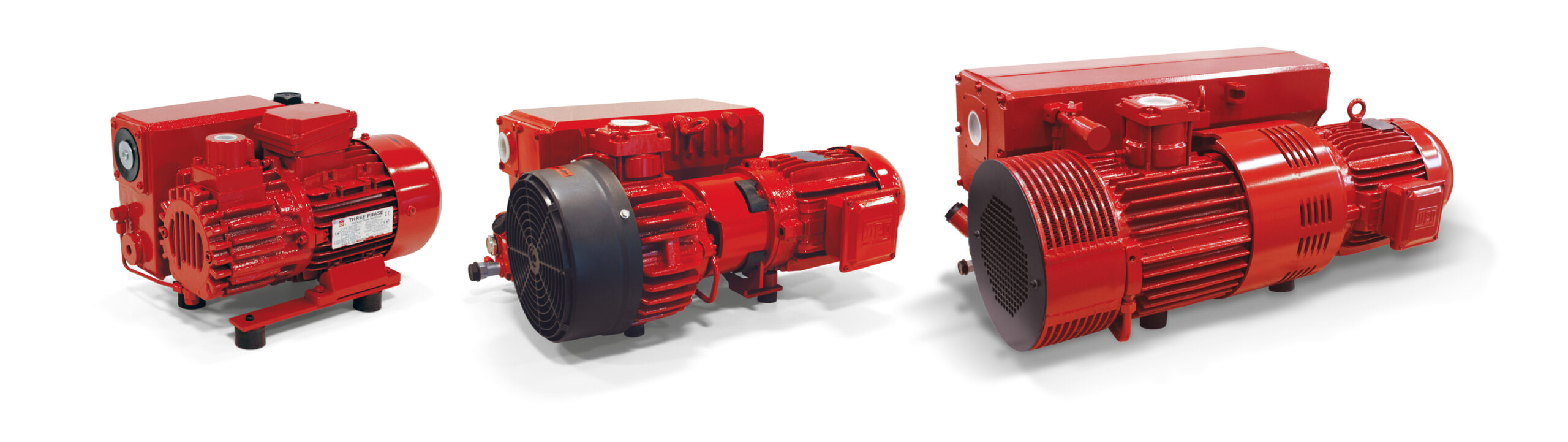

In particular, RVP rotary vane pumps, which are particularly compatible with water vapour, can be used.

The high pumping speed and the reduction of exhaust fumes, thanks to a large oil recovery tank, equipped with microfiber de-oiling cartridges, makes them the ideal solution for drying.

They have small dimensions and are also perfect for continuous use.

Compliant with the latest European standards (IEC60034), they feature IE2/IE3 energy-efficient electric motors and are made with quality materials.

Last but not least, they don’t produce particular noise and don’t overheat during use.

To view technical specifications, download the Vacuum Solutions catalogue at www.vuototecnica.net.